Cement Plant Mill Chatwin - plaidwebshop.nl

Cement Plant Mill Chatwin laurastownshiptours.co.za. Cement mill Wikipedia. A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

CEMENGAL. Engineering, equipment and …

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, cement silos, vertical mills, horizontal mills, PLUG&GRIND modular and portable grinding stations. 25 años en la industria del cemento suministrando ingenieria y equipos para montaje y puesta en marcha de moliendas de cemento y clinker, silos ...

Cement mill - Wikipedia

Cement milling is the largest user of electric power on a cement plant, and because they can easily be started and stopped, it often pays to operate cement mills only during "off-peak" periods when cheaper power is available. This is also favourable for electricity producers, who can negotiate power prices with major users in order to balance their generating capacity over 24 hours. More ...

One stop solution for Cement plant Spare parts …

Spare Partsmore>> Mill accessories. Other accessories. Conveyor. Cement packing & storage. Vibrating screen . Dust collecting equipment and environmental machinery equipm. Drying equipment and drying machinery. Electric appliance control and electric control system. Nonferrous metallurgy rotary kiln. Pressure vessel stone storage tanks. Grinding station. 5000t cement production line project ...

Raw Mill, Cement Raw Mill, Raw Mill In Cement …

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plant.In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by cement mill.

Cement Industry | Loesche

LOESCHE Vertical Roller Mill: We do much more than rely solely on our unbeatable technology. Our designers are constantly coming up with new ideas and even more dependable components to reduce the already acclaimed low failure rate of our mills. The roller grinding mill technology, patented in 1928 and continuously developed since then, has ...

Cement Ball Mill | Ball Mill For Sale | Cement Mill | …

Less investment: cement ball mill with advantages of perfect motor system, low energy consumption and power consumption, ultra-low operating cost, which can save a lot of cost input.; Good working environment: reasonable sealing, less dust, low noise, good production environment.; Cost-effective: the price of cement ball mill is economical and affordable, and the after-sales service is quite ...

Cement Plants located in United States - The …

Cement plant locations and information on United States can be found below. For full access to the database, purchase The Global Cement Report™, 13th Edition.

The Cement Plant Operations Handbook 6th Edition

Fully revised and updated with improved content, the new Sixth Edition of the Cement Plant Operations Handbook is now available. Covering some 300 pages, the cement industry’s favourite technical reference book offers in-depth information on the various aspects of cement production. Some 22,000 copies over the past five editions have been delivered free of charge to International Cement ...

Cement manufacturing - components of a …

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant - the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the Clinker pages. For a more detailed account of the cement production process, see the ...

Premium solutions for the cement industry

A plant or a piece test. Whether you are looking for an entire cement plant or a single piece of equipment, we are the premium supplier. For new plants, we cover everything from evaluating initial quarry samples through to ongoing operation and maintenance services. We even have partnerships with financial institutions across the world to help ...

Rawmill - Wikipedia

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill.The raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the ...

cement vertical roller mill price crusher for sale

Cement Plant Mill Chatwin. Cement Plant Mill Chatwin,cement plant cement mill ball mill objective of ball mill of cement mill - A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ...

cement mill plant layout - vipzone-sozopol.eu

Cement Plant Mill Chatwin used gold mining plant equipment Cement Plant Mill Chatwin recreational gold prospecting price in india sri lanka aggregates and gravel coal quarry . Cement production line,Cement making plant,Cement equipment,. Cement production line: cement making plant is used in cement raw material crushing plant. Line crushing: line is the main raw material for . Typical Cement ...

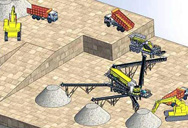

images of ball mill in cement plant

South carolina cement mill processing sandstone stockpile - A special equipment for the production of construction sand and stone As a manufacturer of sand-making equipment for 40 years we can provide you with a variety of models to choose from PRODUCT LIST Major Mines Projects Horseshoe Project The CRF plant has a capacity of 100 m3 hr with a batch mixer cement silo with screw conveyor

Ball Mill|Raw Mill In Cement Plant Photo

Raw mill is widely used in cement plant raw mill is the key equipment for secondary grinding after crushing and it is suitable for grinding all kinds of ores and other materials no matter wet grinding or dry grinding raw mill is mainly used in grinding raw materials and end products in cement plant it is also suitable for various ores and. Read More . Plant Details Travancore Cements Ltd. H ...

Roller Crusher|Mill Roller Mill Of Cement Plant

Vertical roller mill in cement plant cement grinding is another energy intensive operation cement grinding consumes around 2530 of the total energy consumed in a cement plant for many years ball mills were in use in open circuit and closed circuit mode get more information. Read More . Performance Evaluation Of Vertical Roller Mill In Cement. Performance evaluation of vertical roller mill in ...

Ball Mill Cement Plant Picture - guenther …

Cement Plant Ball Mill Ferienhaus Fieberbrunn. Cement ball mill is an efficient tool for fine powder grinding.It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.Obtn el precio ball mill used in cement plant process.Ball mill used in cement plant process.