Cement - KIMA - Process Control

LEADING TECHNOLOGY IN BALL MILL CONTROL. With MillMaster KIMA Process Control offers the most robust, open and easy to handle Advanced Control System in the Cement Industry. Since 1996 this ‘Auto-Pilot’ system was installed in hundreds of cement plants to operate mills fully autonomously.

Rawmill - Wikipedia

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill.The raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the ...

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL …

Ball mills are predominantly used machines for grinding in the cement industry. Although ball mills have been used for more than one hundred years, the design is still being improved in order to reduce the grinding costs. HOLTEC has undertaken Performance Optimisation of the cement grinding circuits by doing process

what is ball mill grinding in cement industry

May 11 2020 · The ball mill is key equipment in grinding industry It is widely used for the cement coal sand fertilizer glass ceramics etc But its final product cost is high as Ball Mill BM grinding Ƞ is lowest 5 when compared with Vertical Roller Mill VRM 10 Roll Press RP 15

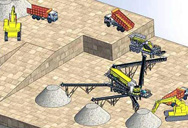

Manufacturing process | Lafarge - Cement, …

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km.

Ball Mills Cement Process - johanklaps.be

Ball Mills Cement Process. A cement mill is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement most cement is currently ground in ball mills and also vertical. ... Process of ball mill in cement industry ...

Ball Mills - Mineral Processing & Metallurgy

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill & ball mills, the ore in order to liberate the minerals. In the stone and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Cement Mill - great-wall.co

The cement ball mill is mainly used to grind cement clinker in cement production process, and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises such as metallurgical plant, stone plant and power plant and so on Our company has more than 40-year experience on the manufacture of cement ball mill, the quality of our product takes a ...

Cement Production: Raw Meal Production in Steps

Cement Production: Raw Meal Production in Steps Perfectly mixed, accurately fed without pulsation, and precisely weighed. The key word is quality! And this quality is achieved during cement production with exactly matched process steps. In the first stage, the raw meal is produced, as described below.

Cement Manufacturing Process | Phases | Flow …

Cement Manufacturing Process Phase IV: Kiln Phase. Kiln is a huge rotating furnace also called as the heart of cement making process. Here, raw material is heated up to 1450 ⁰C. This temperature begins a stone reaction so called decarbonation. In this reaction material …

VRM vs Ball Mill for Cement Grinding - Page 1 of 1

10-2-2016 · VRM vs Ball Mill for Cement Grinding. Good Days! Gentlemen, ... Maintenance costs- high for VRM and low for Ball mill ; Process control/process technology- ball is operation friendlt and simple in operation but VRM requires some PID or control technology. ... 12 issues of the leading cement industry magazine, your choice of complimentary ...

Cement Ball Mill - Market Development Trend - …

Cement ball mill is the core equipment in the production of the cement industry and also suitable for power, metallurgy, stone and other industrial enterprises to mill …

The cement mill

Cement manufacturing - brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media - normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum …

How to use ceramic grinding ball in ball mill of …

1. When loading the mill with empty warehouse, add materials first and then add the ceramic balls. Chinas cement industry has been forced to eliminate the ball mill below 3 meters, so all enterprises in the grinding ball assembly mill, are using electric hoist, lifting …

Cement grinding Vertical roller mills versus ball mills

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, ... cement industry the ball mill was really an epoch-making breakthrough as for almost ... Dehydration of the gypsum added to the cement In the grinding process heat will be generated and the cement …

Optimization of Cement Grinding Operation in Ball …

Optimization of Cement Grinding Operation in Ball Mills. Contact Us » . Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pre-grinders with ball mills.